Date: 7/14/2024

White Bear Photonics, LLC

2157 Randy Ave.

White Bear Lake, MN 55110

Summary

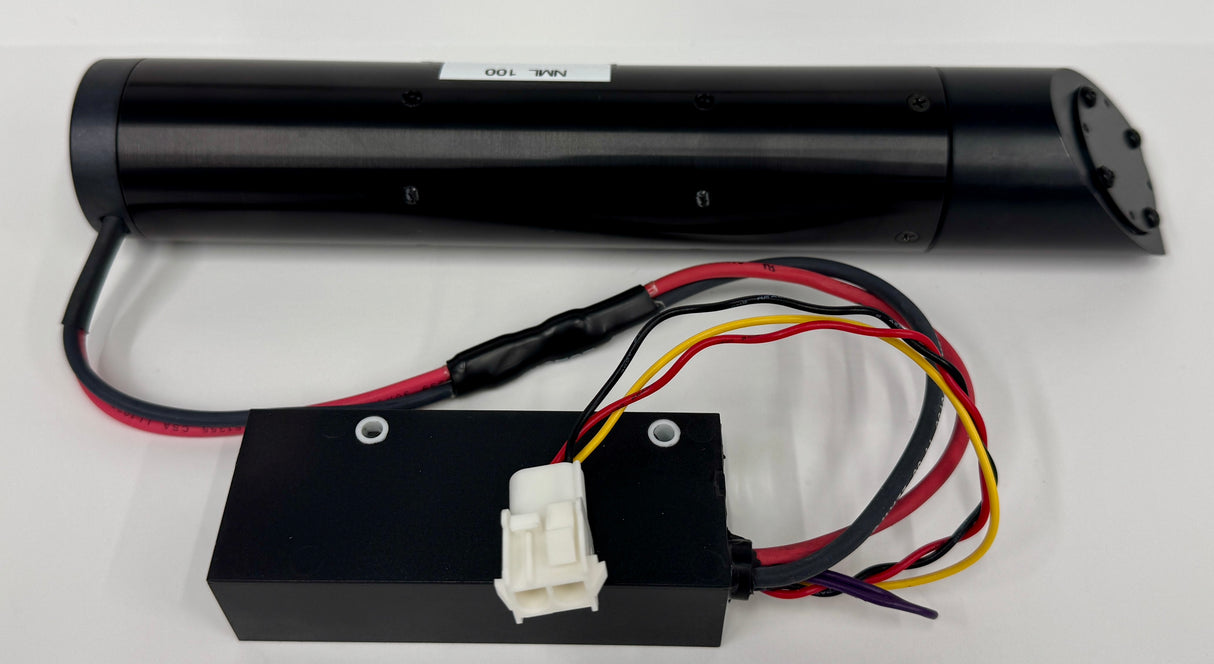

In order, the top three consumables of an FTIR are the desiccant, IR source, and HeNe laser. The HeNe laser is a critical component of the Interferometer and is used to calibrate the instrument as well as control the moving mirror.

Replacement of the HeNe laser is often needed due to:

- High laser gains after alignment (pegged at maximum of 240).

- Scan issues resulting to no scanning, intermittent bad scans, or noisy data.

- No visible laser light in sample compartment or from the laser head (dead laser).

- Old lasers (from the manufacturing date shown on the head) of more than 7 years will often show one or more of these top three symptoms.

Removing the old laser

- Turn off the FTIR.

- Unplug the laser and remove the entire mount (holding the laser).

- Mark on the clamp the position of the old laser on the front of the head (screw), this is so you can match up the new laser head into the same position.

- Loosen the clamps and slide the old laser out.

Installation of the new laser

- Slide in the new laser to same mark and head position.

- Note, the laser can be in any position in the clamp, so marking the position will get the new laser beam in approximately the same position on the Laser detector when re-installing the mount.

- Power the FTIR up.

- You may have to tape down the Interlock switch on the top of the Main Board. The laser interlock will prevent you from making any adjustments. If you push the interlock button down you should see the laser Turn ON.

- When the laser turns on make sure the beam is hitting exactly in the center of the beamsplitter. The center of the beamsplitter has a clear aperture for the laser to pass to and from the interferometer. The clear aperture should have the laser centered and be evenly filled so the diodes (detectors) will produce low gain values when the auto alignment is completed.

- If the beam is properly aligned it will evenly overfill the first (small) pickoff mirror going into the interferometer. There are several stray reflections and one bright beam. When the laser is properly aligned the through the modulator there is one bright beam that will retro-reflect back on the small pickoff mirror and not be present on the card. When properly aligned there should be very little “spill over” retro reflected back to pickoff mirror.

- When completed with best visual alignment, open the Omnic Application.

- Go into Experiment Setup, then the Diagnostics tab.

- Hit Align and verify the alignment has completed.

- When the alignment is complete you should see an interferogram of some amplitude as shown below.

- Close out of Omnic and go into the C-drive->programs->Omnic Folder. Pin the application called MagDiag to the taskbar (so you do not have to hunt for it next time).

- Open MagDiag (note the panels may not look exactly the same as below based on the version of the Omnic software, but the content should the same).

- Then hit the Laser icon you will see:

- Take a screen shot and record the MCoilX and MCoilY (for future reference).

- Hit Laser Gains icon (note: all of the gain values should ideally be less than 100 with a new laser. Take a screen shot of this and record the date of this laser change if all three are less than 100):

- If one of these parameters is 240 the laser will need to be physically re-aligned the so the laser beam is properly hitting all three diodes. In a high laser gain state, the FTIR may still appear to scan, but will be unstable and will intermittently generate bad scans when taking data.

The laser gain panel is a real time monitor of the voltages from the laser detector. If one of the parameters (X, Y or R) are high, you (carefully) move the laser within the clamp (loosened) either right or left or rotate the tube to reduce increase the voltage level(s). This adjustment is very sensitive and coarse, make sure you make small tweaks when attempting this step.

If you make any adjustments in this final stage in maximizing one or all of the voltages, you need to re-align the system back in the Omnic application (step 12). This will reset the gain levels (where you check it again in MagDiag). If you adjusted and obtained higher voltages in the Laser Gain panel, then you should see a reduction of the gain value(s) with this alignment process. When finished this iteration (auto align, adjust, auto align…) will assure the system will remain stable as the laser ages with lower power over time.

Final Comments

Based on the instrument, this process may not result in the instrument successfully scanning if the instrument was not used for an extended period or time or came out of storage. Since nearly all FTIRs use KBR optics (salt optics), they can easily be damaged by humidity. When this happens there will be a significant amount of scattering in HeNe laser form the KBR beam splitter in the interferometer. Secondly, if the beam splitter is partially “fogged”, this will result in high laser gains (all three, X, Y, and R) after the auto alignment. In general, when all three laser gain parameters are high it is usually a result of a weak laser or a fogged beam splitter. When one or two of the laser gain values are low (normal, and well less than 100), with the other(s) high at 240 it becomes an alignment issue with the laser beam either not being uniform or off the detector.

The laser gains window shown above is only accessible when Omnic application is closed. This means you need to close out Omnic, then open MagDiag for access to this window. This window is convenient since it provides a real output of the voltages seen by the Laser Detector. The other method of observing these voltages is by connecting a scope to the three test points on the preamp board as described in the Thermo Service Manual. We have found the MagDiag “shortcut” described above to be easier and safer to use.

Executing Align in the Diagnostics window has a two-step process. First it establishes the proper gain values read from the HeNe laser. During this process it is monitoring the laser detector board just outside the interferometer. Once the gain levels are established the instrument will start scanning and you will then see an interferogram to appear. During next step called the “Fine Alignment”, the galvo mirror on the reference mirror will optimize the IR beam on the IR detector (on the left of the sample compartment). You will see the amplitude of the interferogram go up and down, until the maximum is found. Once found the galvo mirrors are parked at the voltages shown for McoilX and McoilY in the window shown in step 12.

Note the final amplitude of the interferogram will be related to the signal to noise after the Align process. If the amplitude is lower than 3 at Gain=1, most likely the IR source is getting close to end of life. If there is no amplitude, and the system is scanning the IR source is either dead or switched off.